Splicing electrical wires seems easy; Put two bare wires together and hold them together through twisting and it’s done. New splicing methods are coming up every day, claiming to be safe and reliable. NASA is preparing specific standards for securing wire connections. Let’s learn more about the different wire splicing methods and understand which is the best.

Table of Contents

- What is Wire Splicing?

- Wire Splicing Technique for Custom Cable Assembly

- Different Methods of Splicing for House Wiring

- Wire Splicing Methods in Your Vehicle’s Wiring Harness

- Emergency Splice for Low Voltage Only.

- Conclusion

What is Wire Splicing?

Wire splicing means joining the bare ends of two conductors so that there is permanent termination and a solid mechanical bond. You can complete the connection either through soldering or crimping.

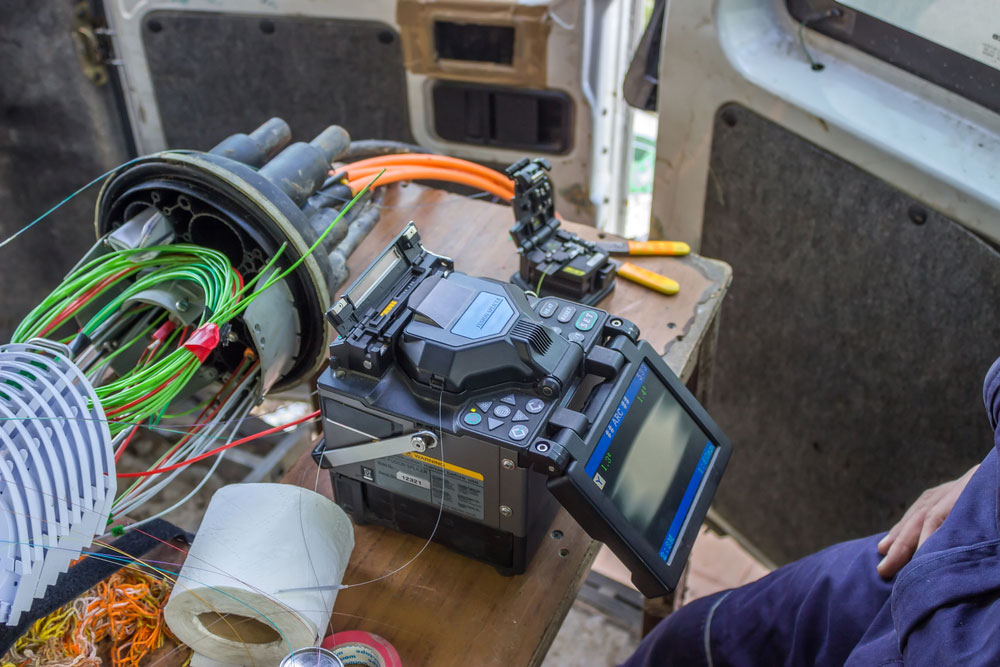

Image: technician splicing fibers

Wire Splicing Technique for Custom Cable Assembly

A critical part of the custom cable assembly is splicing. You can do splicing using several methods. However, if you know their benefits and disadvantages, it helps you design your cable assembly.

Heat shrink splice

Heat shrink splicing is the simplest method requiring minimal labor and resources. You can complete this splicing under the following steps:

- First, take a heat shrink sleeve. This sleeve has a ring of solder inside it.

- Now, insert the ends of the conductor into the sleeve.

- Now, apply the heat gun. Due to heat, the solder will liquefy and will set the connection. Also, the sleeve will shrink so that it seals the connection properly.

Though simple, it is not very reliable; it is best to use this method in field maintenance when no soldering iron is available.

Image: the process of applying a heat shrink on copper cable

Butt Splice

The butt splice looks like a heat shrink splice, but the difference is that it uses a crimp connector instead of solder. You can complete this splicing through the following steps:

- First, insert one of the stripped wires into the butt splice’s end. Push it until it reaches the center of the splice.

- Secondly, take a wire crimper and crimp the splice around one-quarter away from the splice end. It will hold the wire in place.

- Third, repeat the same process with the other wire. Insert that from the other end of the splice and crimp it.

- Now, slide in the heat shrink tubing over the splice and completely cover it. If the heat shrink sleeve is loose, you can crimp it to put it in place.

- Finally, take a heat gun and heat the heat shrink tubing. Keep rotating the wire or the weapon for even shrinking from all sides.

The butt splice is a reliable method of wire splicing and is the standard crimp connector. And it is a cost-effective method but requires manual effort.

Solder splice

Soldering is the most general and reliable method among the wire splicing methods. Follow these steps to complete soldering:

- First, take the wires you want and set a manual connection. You can do this using different methods, such as twisting them together.

- Now, heat the soldering iron and apply the solder to the twisted part until it liquefies and envelopes around the wire connection.

- Finally, use a heat shrink sleeve to seal the connection completely.

Though soldering forms the most reliable and secure connections, it is a labor-intensive method. Individuals performing soldering must have electrical knowledge; otherwise, issues like cold solder or wire insulation damage are unavoidable.

Image: soldering iron

Machine splice

Wire splicing through auto-splice machines is the most effective method of wire splicing. Regarding reliability, it matches soldering but is more effective than that. Machine splicing requires the following steps:

- Firstly, cut, strip and clean the wire.

- Now, insert the wires into the auto-splice machines.

- Then, the machine will form a crimp connection around the wires. For this, it uses brass-coated copper wire wound around a spool. The machine cuts the wire, stamps it, and forms a crimp connection.

- Finally, you can use heat shrink tubing to seal the connection.

Auto splice machines can perform wire-to-wire splices and also wire-to-board splices. However, it is not suitable for wires with 14 gauge or higher wire gauges. For this, you will need solder splicing, and auto splicing is a more straightforward method and does not need training and expertise like soldering.

Different Methods of Splicing for House Wiring

If you want to install an electrical fixture in your house, you will need to splice the wires to connect the main cables of the institution and the home’s line voltage. Even small projects like repairing some fixtures also require spliced wires. So, if you know the proper splicing, you can save money and install your fixtures safely.

Before splicing wires

Firstly, unplug the equipment or the device which needs splicing. Before unplugging it, turn off the primary circuit to avoid shocks.

Secondly, strip around one inch of insulation with the help of a wire stripper in both wires. For this, clamp the wire in the two-size small hole of the stripper and then pull it.

Lastly, slide in a piece of heat shrink tube (around 3 inches) onto any one of the wires. You can use this shrink sleeve for the final sealing of the wire connection.

Different wire splicing methods

With the twist on wire-cap

- First, hold both the stripped ends of the wire so that they are close. Do not coil or twist the wires.

- Secondly, hold a cire cap on the top of the wires and twist it on with fingers in the clockwise direction for 5 seconds. The spring inside the wire cap becomes tighter as you spin it. As a result, the twisted wires will wrap inside the lid.

- Finally, wrap an electrical tape around the wire cap and the stripped part of the wires to completely cover it. You can use colorful tape to mark the cables. Once you wrap it correctly, cut the tape.

Installing a butt splice

Making a lineman’s splice

- First, create a 90-degree angle by bending exposed parts of the wires. Ensure that both sides of the curve are at least 1.3cm so you can quickly wrap the wires.

- Now, hook the wires so that their corners touch each other. After joining, you will see one wire is upright, and another is in a down position.

- Then, wrap the vertical wire around the straight portion of the other wire and repeat the same with the wire in the down position. Make sure that you cover the wires tightly to make a secure connection.

- After that, take a soldering iron and solder the coils tightly.

- Now, slide a heat shrink sleeve over the complete splice to hide all the exposed wires.

- Finally, heat the shrink tubing with the help of a heat gun and continue heating until it gets tightly wrapped around the wire connection.

Wire Splicing Methods in Your Vehicle’s Wiring Harness

You will see the wire splicing if you work around cars, be it replacing a bulb, installing a new stereo system, or fitting an EFI kit. As in all electrical systems, it is equally essential for vehicles to make guaranteed electrical connections. The lineman’s splice or the western union splicing method is an easy, solid, and simple method of wire splicing.

Emergency Splice for Low Voltage Only.

You can use an emergency splice on the low-voltage electrical systems (5-10 volts). However, do not leave an emergency splice and replace an emergency splice with the proper splice whenever possible. If your house wiring has issues, do not try an emergency splice.

- First, strip the ends of the wires by stripping the insulation

- Now, twist both the ends together

- Then, wrap electrical tape around the twisted and exposed parts of the wires.

Conclusion

Splicing helps you set cable connections so that you do not need to install new ones. It is a low-cost alternative to installing new cables. It is possible to handle minor electrical repairs and replacements if you follow all safety norms. However, if you do not feel safe doing these electrical works on your own or if the issues are more significant, it is better to call an electrician. If you are to seek help, Cloom is here. Call us today, and our expert technicians will help you through all types of wire splicing.