There are two types of network cables, i.e., category 5e or CAT 5e and Category 6 or CAT 6. You can find both in solid and stranded formats. In the reliable format, a standard 4-pair cable has eight solid wires. In a stranded conductor, each conductor has multiple wires twisted around each other. So, in 4-pair wires, there will be a total of 56 stranded wires. These differences in conductors make them suitable for different applications. In this article, we will give you a brief idea about the Stranded vs. Solid Wire so that you can decide which to pick.

Table of Contents

- Stranded vs. solid wire: Basics

- Solid vs. stranded wire: Design

- Stranded wire vs. solid wire: Comparison of advantages and disadvantages

- Stranded vs solid wire AWG chart

- Stranded vs. solid wire amperage chart

- Solid vs. stranded wire: Industry Standards and Environment

- Solid wire vs. stranded wire: Applications

- Conclusion

Stranded vs. solid wire: Basics

In any twisted copper cable, the words stranded and solid define the conductors’ construction in the cable. A combination of two numbers specifies the left cable. For example, a 7*32 or 7/32 cable has seven strands of 32 AWG wire in each conductor. On the other hand, a single number represents the solid cable, and this number specifies the size of the conductor—for example, 24 AWG wire.

What if one gauge size represents both the stranded and solid cable? Remember, it doesn’t matter whether the conductor has multiple strands or one solid wire; the overall size remains the same.

However, when it comes to the performance, you must know that as the stranded wire has thin strands, it has more insertion loss and thus shows 20-50% more attenuation than a solid wire. Also, as the surface area of a solid wire is more than a stranded wire, it is less susceptible to corrosion and less affected by vibration.

Image: bare stranded wire

Solid vs. stranded wire: Design

Solid and stranded wires generally have a circular cross-section area. However, you can find wires in square, hexagonal, rectangular, and other cross-sections.

Several strand types in wires in the electrical industry offer unique characteristics to a stranded wire.

Concentric strands: This strand has a central core or wire, and many layers of helically arranged wires surround this central core. Every successive layer has more wires than the previous layer, and each layer is placed opposite to that of the preceding layer.

Bunch strand: There is no geometric arrangement in this strand. You will find multiple strands twisted together in one direction.

Rope strand: Concentric-stranded groups twist together to form a rope-like structure.

Sector conductor: This stranded conductor has a cross-section similar to a circle’s section. A cable with multiple sector conductors has a smaller diameter than a cable with round conductors.

Compact strand: This strand can have a sector or round conductor with layers stranded in the same direction. It is then rolled to form a pre-decided ideal shape. The finished conductor has a smaller diameter, smooth surface, and no air spaces.

Image: solid wire in yellow-green insulation for electrical grounding

Stranded wire vs. solid wire: Comparison of advantages and disadvantages

By comparing their pros and cons, you may know which cable suits your application.

Wire current-carrying capacity: Compared to the stranded wire, a solid wire has a smaller surface area and is thicker. Also, there are air gaps in multiple strands of stranded wire. So, this makes a solid wire a good conductor. However, it doesn’t mean that this solid wire will have a better current carrying capacity. You can use solid wire in various frequencies to bear varied electrical characteristics.

Flexibility: As a stranded wire comprises multiple strands, it is more flexible, and it can withstand flexing and repetitive bending without getting damaged. So, it is better to use stranded wire in flexing applications to avoid repeated expenses. However, if you talk of terminating a stranded cable, you will see that multiple strands become loose and weak over time. On the contrary, solid wire holds its shape in IDCs on jacks, connecting blocks and patch panels for a long time.

Routing: A stranded wire is suitable for routing applications as it gives better bending capabilities. So, you can easily route cables even if you have hurdles in the wiring path.

Stranded vs solid wire AWG chart

A stranded wire has seven strands, the lowest number. One strand is in the middle, and 6 surround this middle strand. For geometrical reasons, the following number in the strand is 19. Mainly, large AWG wires use such a high number of strands.

Stranded vs. solid wire amperage chart

The conductor’s size mainly determines the current carrying capacity, and the American Wire Gauge standard denotes the size of the conductor. So, as said above, the overall conductor size of stranded and solid wire remains the same if they are using the same gauge wire. Thus, you can say that the current-carrying capacity of the same gauge stranded and solid wire is primarily the same.

Solid vs. stranded wire: Industry Standards and Environment

According to the TIA and ISO/IEC standards, a 90-meter horizontal permanent link needs a solid cable. In a 100-meter channel, you can use stranded lines of 24 and 26 AWG sizes for patch cords and 10-meter lengths. As the flexibility of a stranded cable is more, it is good to use them in equipment connections and cross-connections as cables here need repeated flexing and bending. Further, in 10-meter length, the insertion loss and resistance do not affect the overall channel performance. However, a stranded cable with 28 AWG sizes is not suitable for patch cords as they have more insertion loss and resistance.

In some open office spaces where professionals need a more flexible cable system, standards allow more than 10 meters of stranded cables. However, if you use a stranded cable for more than 10 meters in a channel, you have de-rate the overall channel length according to industry standards. This de-rating is to accommodate higher insertion loss and high DC resistance.

According to industry standards, the wire gauge is a determining factor in de-rate a stranded cable. The higher gauge or thinner lines have a high de-rating factor and vice versa. For example, the de-rating factor for a 26 AWG gauge cable is 0.5, and that of a 24 AWG-stranded line is 0.2. Furthermore, a 22 AWG gauge cable does not require any de-rating.

Here is the formula to calculate the overall channel length.

Cat 5e and cat 6: C=(102-H)/(1+D)

Cat 6A: C=(105-H)/(1+D)

T=H+C

Where:

H=horizontal cable length

D=de-rating factor

C= total stranded cable length

T=total channel length

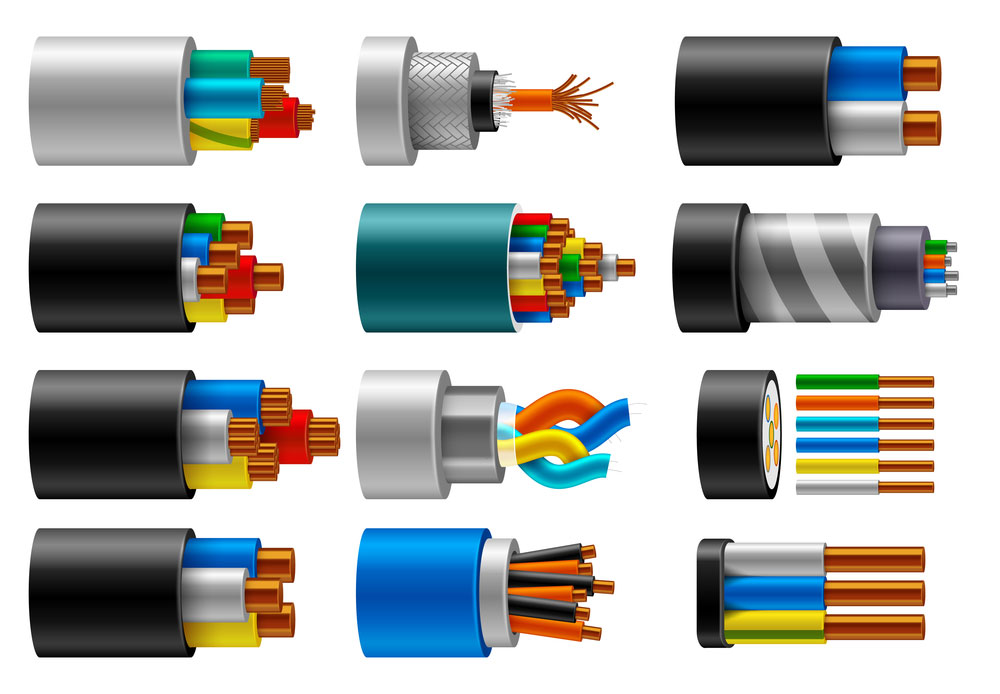

Image: cable wire, electric, fiber, or copper power in cut

Solid wire vs. stranded wire: Applications

According to the standards, in the patching areas of telecommunication rooms and office areas, a stranded cable is in use. However, in power over ethernet, solid patch cords are in use. The stranded wires have high insertion loss and DC resistance which can degrade in high-temperature conditions. When using a stranded cable in PoE, some energy dissipates as heat, which leads to an increase in the temperature of the line.

In telecommunications rooms, the environment is relatively controlled, and there are no issues in using a stranded cable. However, stranded cable patch cords can create a problem when installing LED lights and security cameras in the ceiling. So, a good thumb rule says that a solid path cord is more advisable in uncontrolled environments with high bending needs. Even if you use a stranded cable in such a situation, remember to keep them short up to 5 meters.

One has to de-rate the channel length according to industry standards for high-temperature environments.

Conclusion

You must weigh and consider all needs when choosing stranded or solid wire. These include long-term costs, environmental factors, loads, applications, and durability. If you are an OEM or run a small business, you must seek advice in this direction from a qualified electrician and electronic experts in the field. Please don’t hesitate to give us a call.