While working with the cable industry, you might explore different options for cable insulation. Although many options are available, the PVC Wire VS. XLPE Wire insulation prevails.

Both options have capacities and uses, such as resistance to abrasion, moisture resistance, and chemical resistance.

However, due to the differences in their physical properties, their working conditions differ. Let’s look into the details for PVC wire vs. XLPE wire.

Table of Contents

- What is PVC?

- PVC Wire VS. XLPE Wire: What is XLPE?

- PVC Wire VS. XLPE Wire: Comparison of Properties

- Conclusion

What is PVC?

PVC stands for Polyvinyl Chloride, a polymer of vinyl chloride. It’s resistant to acids, alkalis, and some chemicals. It’s also chemically stable.

When used, the temperature cannot go above 60 ⁇ C; if it gets too cold, it will get hard. There are two kinds of polyvinyl chloride: hard plastic and soft plastic.

The soft ones are mostly made into films, which can be used as packaging materials, rainproof products, agricultural seedling-raising films, insulation layers for cables and wires, and products that look like leather. On the other hand, rigid PVC makes pipes and plates.

Using these pipes carries water and fluids that do not react with corrosion. Additionally, the plates are used as the walls and floors of different storage tanks.

Useful PVC Cables applications

PVC cable comes in many different types, such as PVC-sheathed power cable and PVC-insulated flexible cable. They have low cost, high tensile strength, good chemical resistance, and better flexibility. Thus, you can use low-voltage PVC cables for

- Domestic home appliances wiring,

- Internal wiring of light circuits in factories,

- House wiring

- The power supply of office automation.

Caption: PVC Sheathed Copper Cable

PVC Wire VS. XLPE Wire: What is XLPE?

Chemical or physical methods transform polyethylene molecules from a linear chemical structure to a three-dimensional framework. Polyethylene’s strength is increased by converting it to a thermoset cross-linked form. It has excellent conductivity, aging resistance, mechanical properties, and impact resistance.

Improved PE performance necessitates cross-linking technology. Thus, Cross-linking the PE improves its mechanical properties and environmental factors such as cracking, synthetic corrosion, creep, abrasion, and electrical properties.

Additionally, you can increase the thermal resistance of Cross-linked Polyethylene from 70°C to over 90°C, greatly expanding the range of applications that PE can solve. Thus, the manufacturer has widely used XLPE in films, pipes, cable materials, and foam products.

PVC Wire VS. XLPE Wire: Useful XLPE cable applications

Moreover, cross-linked polyethylene insulated power cable conductors can work at 90 degrees Celsius for long periods, higher than the working temperature of polyvinyl chloride insulated cables and simple polyethylene insulated cables.

Due to the drop and other advantages, laying is not constrained. XLPE insulated cables can be beneficial in the following applications

- They can perform well in working voltages of around 240V to 500 VK. Also, its temperature range is good to use in heated areas.

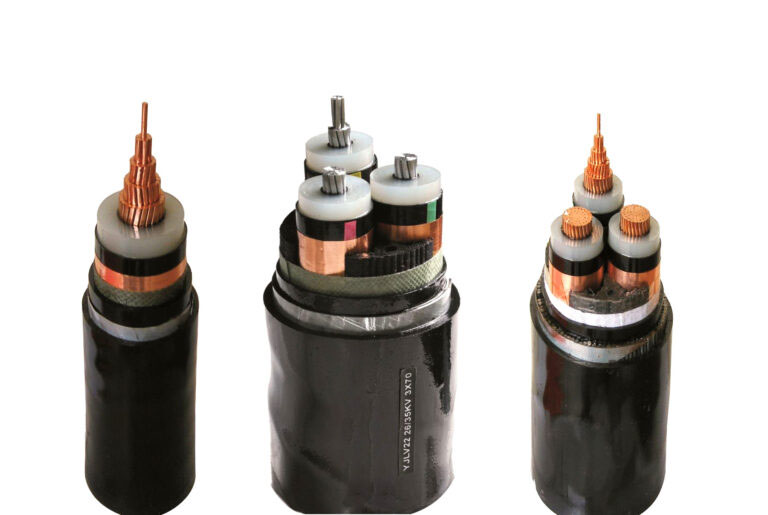

- XLPE can provide insulation resistance to both single-conductor and multi-conductor cables.

- Moreover, you can use XLPE with either copper or aluminum as conducting material.

- Also, you can use the XLPE with HT / LT Aerial Bunched Cables

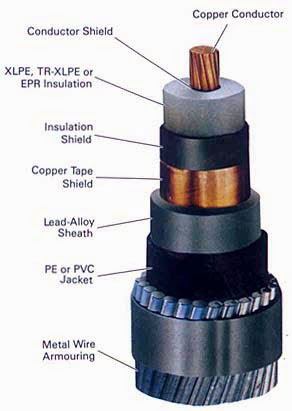

- Additionally, XLPE can provide insulation to unarmored, strip-armored, wire-armored, or Tape armored cables.

Caption: XLPE insulated Power Cable Structure

Source: http://electrialstandards.blogspot.com/

PVC Wire VS. XLPE Wire: Comparison of Properties

Some prominent differences between XLPE and PVC cables are

- The heat resistance of XLPE cables reaches up to 90 degrees centigrade. On the other hand, the temperature resistance of PVC only reaches up to 70 degrees Celsius.

- As the Polyvinyl Chloride cables burn due to high current, it releases toxic fumes of hydrochloride acid. In addition to HCl, PVC produces other chemicals and a large amount of black smoke. Conversely, the XLPE does not produce toxic gases while burning.

- If you use the cables in places with current surges, you should use XLPE. The XLPE cables have higher current carrying capacity and overload capacity than PVC, even if you use the same conductor.

- Cross-linked polyethylene cables have longer service life than PVC insulation. According to studies, the thermal life of PVC cables is 20 years in a better environment. At the same time, the XLPE can last up to 40 years in dry locations.

Caption: Single and Multi-conductor Insulated Cables.

Source: https://www.zonegemma.org/

Conclusion

PVC Wire VS. XLPE Wire is a type of insulation that you can find on wiring cables. PVCs are low-cost while providing high tensile strength and good flexibility. On the other hand, XLPE has a suitable temperature, stress, UV light, and Oxidation resistance.

Hence, you can use PVCs in-house wiring, whereas XLPE in critical environments.

Here at Cloom, we offer wiring harnesses and cable assemblies with types of jackets and insulation, so your connection is made with attention to detail.