Several electrical components of vehicles function due to automotive wiring harnesses. Failure can put many lives at stake, for example, a malfunctioning harness delivering power to the safety sensor. Try to pick products that are carefully designed and of high quality. Let us know about these auto-wiring harnesses in detail.

Table of Contents

- What are Auto Wiring Harnesses?

- Standard Automotive Wiring Harness Circuits:

- Standard Auto Wiring Harness Components:

- Applications of Automotive Wire Harnesses

- Benefits of Automotive Wire Harnesses

- An In-depth Look at Automotive Wiring Harness Markets:

- Your Wiring Harness Shopping Checklist

- Conclusion

What are Auto Wiring Harnesses?

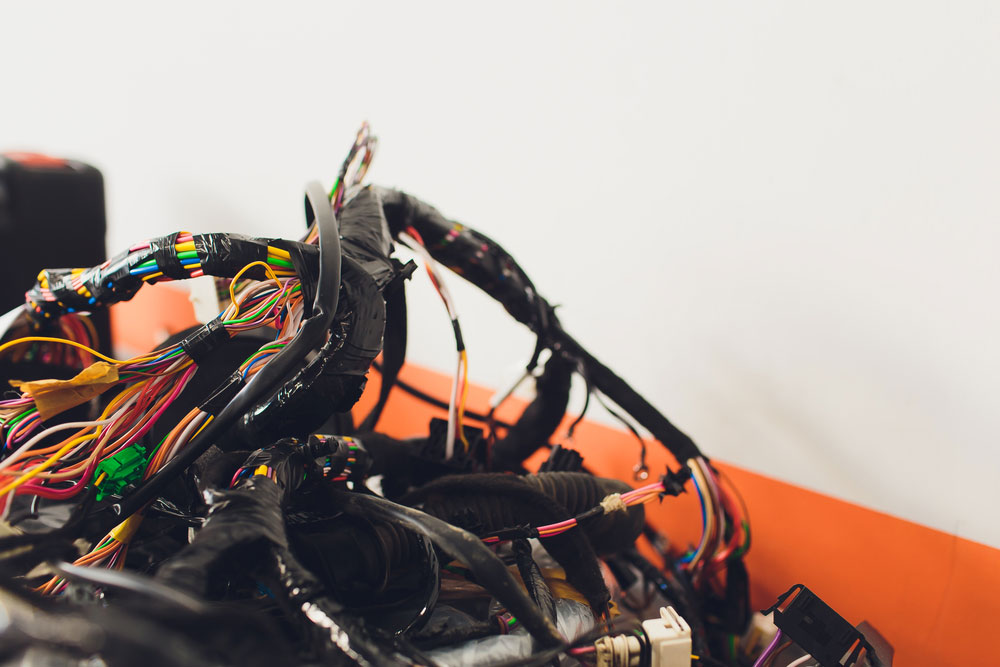

While designing and manufacturing an automotive wiring harness, keeping a vehicle’s dimensions and electrical requirements in mind is essential. Every car has an assembly of electrical cables, wires, connectors, and terminals that help transmit information and power. This assembly is known as the automotive wiring harness. The harness, then, integrates into different parts of your vehicle, like the chassis, dashboard, body, engine, and others. This harness transfers power to various electrical devices, making the car functional and enhancing its safety.

The world automotive wiring harness industry has different segments based on

- Propulsion: ICE vehicles, hybrid vehicles, and electric vehicles

- Materials: copper, aluminum, and others

- Voltage: low voltage and high voltage

- Type of vehicle: two-wheeler, commercial vehicles, or passenger cars

- Application: HVAC, chassis, body and lightning, cabin, dashboard, and others

Image: car wiring and car system

Standard Automotive Wiring Harness Circuits:

A basic auto wiring harness has 12 circuits or wire lengths, each having a specific purpose. It also has a fuse holder in the fuse block for every course. These are:

- Radio

- Turn signals

- Wipers

- Stop lights

- Gauges

- Hazard flasher

- Horn

- Dash lights

- Parking lights

- Distributor

- Heat and A/C

- Taillights

Each of these circuits serves as a crucial wire harnesses accessory; thus, most harnesses have at least these 12 circuits. However, some vehicles also have extra accessories apart from these. These vehicles come in 18 courses. The additional six circuits are for power accessories like:

- Power locks

- Electric fan

- Power locks

- Electrical fuel pump

- Radio B+ memory

- High-level stop light

Apart from these, some other vehicles have 24 circuits where additional six courses control additional accessories, including:

- Clock

- Dome light

- Glove box light

- Lighter

- Under hood light

- Trunk light

Standard Auto Wiring Harness Components:

An automotive wiring harness has different parts and components, each serving a specific purpose.

Relay

Auto wiring uses a relay for high load circuits. It is an electrically actuated switch designed for a high current course. In vehicles, the ignition switch actuates the relay, transferring current to the starter. Relay uses a low current to actuate a more powerful current.

Fuse

The fuse mainly protects the electrical accessories of a vehicle whenever there is a short circuit in the vehicle’s electrical system. You can call it a sacrificial circuit that will melt or burn at a current level. For example, a 6-amp fuse will burn out if it carries a current of more than six amps.

Earlier, vehicles used glass-type fuse; however, blade fuse has lesser susceptibility to damage than glass tube type. Nowadays, vehicle electrical system uses blade fuse style because of their reliability and easy-to-identify feature. Also, blade fuses are very affordable.

Fuse Block

It is the central point where you can keep all the fuses to find a fuse quickly in case an accessory becomes non-functional.

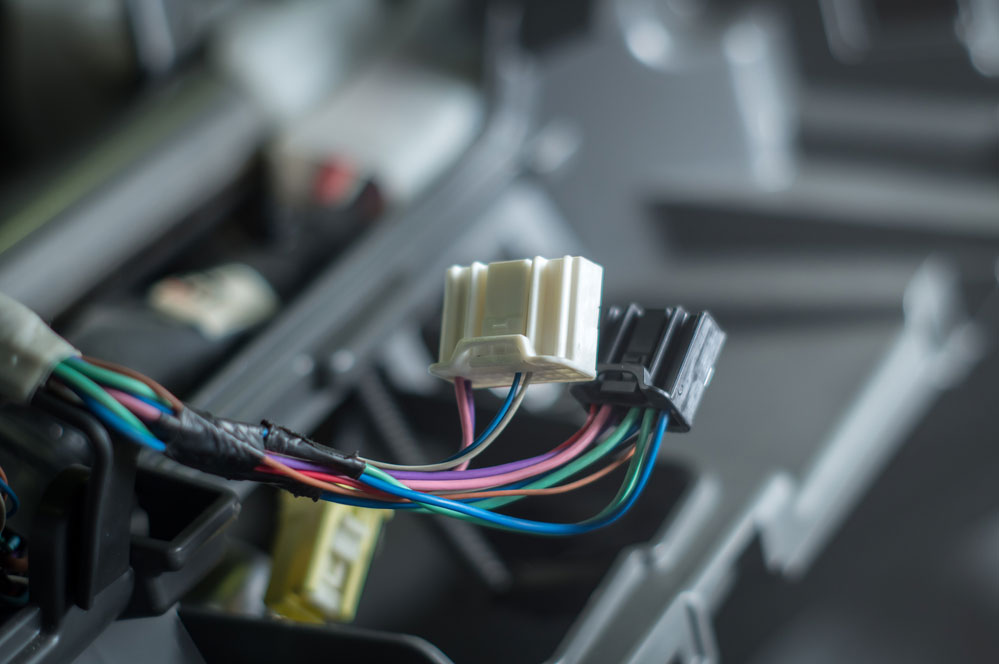

Connector

The connector connects the length of the wire to the fuse block, accessory, and switch. The type of connector varies according to the application. There are simple connectors (ring terminal or spade) or complex (rugged and waterproof weather pack connectors).

Copper and brass connectors are the best. On the other hand, aluminum connectors have conductivity but tend to oxidize very quickly, decreasing their conductivity. However, due to aluminum’s affordability, most auto wiring harness manufacturers use aluminum connectors.

Connectors help connect in two ways: crimping and soldering.

Wire

Automotive wires are low voltage copper wires having standard specifications as 0.5, o.75, and 1.0. 1.5, 2.0, 6.0, 4.0 sq. mm. each with specific load current value.

- 0.5-gauge wire– used for door lights, dome lights, indicators, and instruments

- 0.75 gauge- used for front and rear lights, license plate lights, and brake lights

- 1.0-gauge wire: used for fog lights and turn signals

- 1.5 gauge: used for horns and headlight harness

- The power cord can use 2.5 to 4 sq. mm wire.

While selecting wire, it is essential to look at max. The current value of the load. For example, a positive power line in a car wire or the battery override cable use more than ten sq. mm wires.

Image: automotive connector

Applications of Automotive Wire Harnesses

Two-wheelers, utility vehicles, four-wheelers, and commercial vehicles use auto wiring harnesses. The body wiring harnesses embed into door locks, interior electrical components, dashboards, and power windows. Similarly, engine harnesses embed into cruise control systems, lock braking systems, speed sensors, and fuel injection systems.

Benefits of Automotive Wire Harnesses

- Less installation time: Auto wiring harness comes in a single unit, and it is always easier to install a single unit than multiple wires in the care system. Further, it also reduces the chances of false wiring connections.

- Less risk of short-circuiting: in a harness, multiple wires combine to form non-flexible bundles, so it is safer to use these bundles than loose wires.

- A great performer in harsh environments: as auto wiring harnesses comprise durable materials, the reins are durable too. As a result, they can perform well even in extreme environmental conditions or applications requiring heavy current loads.

- Improved fuel efficiency: automotive wiring harness helps improve all vehicles’ fuel efficiency.

- Excellent performance in hybrid cars: nowadays, hybrid vehicles are in high demand. As automotive wiring harnesses can perform well in harsh conditions, they are the best options for hybrid cars as they can quickly transfer high currents in extreme conditions. These harnesses can handle high winds, resist heat, and prevent electromagnetic noise.

An In-depth Look at Automotive Wiring Harness Markets:

Generally speaking, there is a high demand for auto wiring harnesses because of:

Increased adoption of electric vehicles:

Across the globe, different governments are trying to promote electric vehicles because electric vehicles help in reducing pollution and are environmentally friendly. As electric cars run on electricity, there is a considerable role for electric wiring harnesses in these vehicles.

Development of vehicles with advanced safety features:

Many automobile manufacturers are upgrading vehicles by providing improved safety and security features. These include advanced driving systems, airbags, etc. Safety systems like Lane Departure warning systems, Autonomous Emergency Braking, and other features need good quality electric wiring harness systems.

Automotive trends create new challenges for wiring harness development:

The wiring harness industry faces new challenges due to new technologies and a high influx of start-ups. They should consider the number and complications of these technology features in their vehicles, affecting the harness weight, cost, and bundle diameter. Other autonomous drives, driver support, electrification, connectivity features, and artificial intelligence burdened the wire harness factories.

Image: plastic fuse box inside the engine compartment, visible fuses, relays, and cable harnesses

Your Wiring Harness Shopping Checklist

Looking at the role of auto wiring harnesses in the auto industry, you must pick the right quality and type for your vehicle. How do you do that? Well, the best way is to get answers to these two questions.

How many circuits do you need?

A circuit is a set of wires that connect an automotive electrical component to the harness. For example, there are two circuits for headlights, 1 circuit for the glove box, etc.

Whether the harness you are buying has good quality?

All wiring harnesses look the same, with many wires having connectors. So, it becomes difficult to tell which is better and which has terrible quality. You need to consider these three points to get an answer to this.

First of all, see the type of connection of connectors. Connectors are either attached through crimping or crimp and solder connection. Not all the strands of wires may be included in a crimped connection. As a result, less conduction and more resistance lead to voltage loss. When voltage is low, some components may fail to work. On the other hand, in crimp and solder connections, there is no problem even if you leave some wire strands, which is essential for vehicles used for racing or driving off roads. Generally, all vehicle manufacturers use crimp and solder connections.

Secondly, see if you can expand the harness even if you don’t want to increase the number of circuits. It is essential because an expandable harness can accommodate higher amperage than the number of courses. Also, an expandable harness ensures minimal voltage loss across all systems, ensuring that all components function well even in hot and humid conditions.

Lastly, it is essential to discuss a few things with technical support. Asking questions becomes more critical if you are opting for some custom harnesses. What you ask does not matter. What matters is the confidence and the quality of the answers you get. Some of the questions that you can ask are: “Is harness expandable?”, “Are connectors made of aluminum, copper, or brass?”, “Is the harness compatible with the 100-amp alternator or 80 amps?”

Conclusion

If you have any special needs regarding automotive wiring harnesses, contact us. We are an industry leader in wiring harness production and can manufacture products based on your wire and cable specifications. We can provide any wiring loom for any vehicle, following all industry standards. Whether you own a streetcar, race car, side-by-side, off-road vehicle, aircraft, or any military vehicle, we promise to deliver you low-priced, high-performance automotive wiring harnesses.